2025 Compostable Packaging Trends: How Top Companies Are Embracing Biodegradable Solutions

- Share

- Issue Time

- Sep 28,2025

Summary

Explore 2025 compostable packaging trends as major corporations adopt biodegradable solutions. The market is projected to grow from $112B to $232B by 2034. Discover how PLA-based packaging, paper alternatives, and PBAT-PLA blends transform retail and foodservice. Case studies from Unilever, Starbucks and Tesco demonstrate environmental benefits while meeting EU regulations. Torise Biomaterials provides expert insights on certified compostable solutions driving the circular economy forward.

As we advance into 2025, compostable packaging trends are reshaping the industry, driven by global plastic bans, consumer preferences for eco-friendly options, and corporate sustainability goals. With over 54% of consumers actively choosing products with sustainable packaging in recent months, the global compostable packaging market is projected to grow from USD 112.49 billion in 2025 to USD 232.47 billion by 2034, at a CAGR of 8.4%.

This surge emphasizes plant-based materials like PLA (polylactic acid) and PBAT (polybutylene adipate terephthalate), which support circular economy principles by decomposing into nutrient-rich soil and reducing landfill waste.

In this article, authored by the Torise Biomaterials team—with 14 years of expertise in biodegradable resins and certified compostable products—we explore key 2025 compostable packaging trends through verifiable case studies from leading companies. These examples, drawn from official reports and announcements, demonstrate real environmental impacts and business advantages.

Trend 1: PLA-Based Compostable Packaging for Retail and E-Commerce

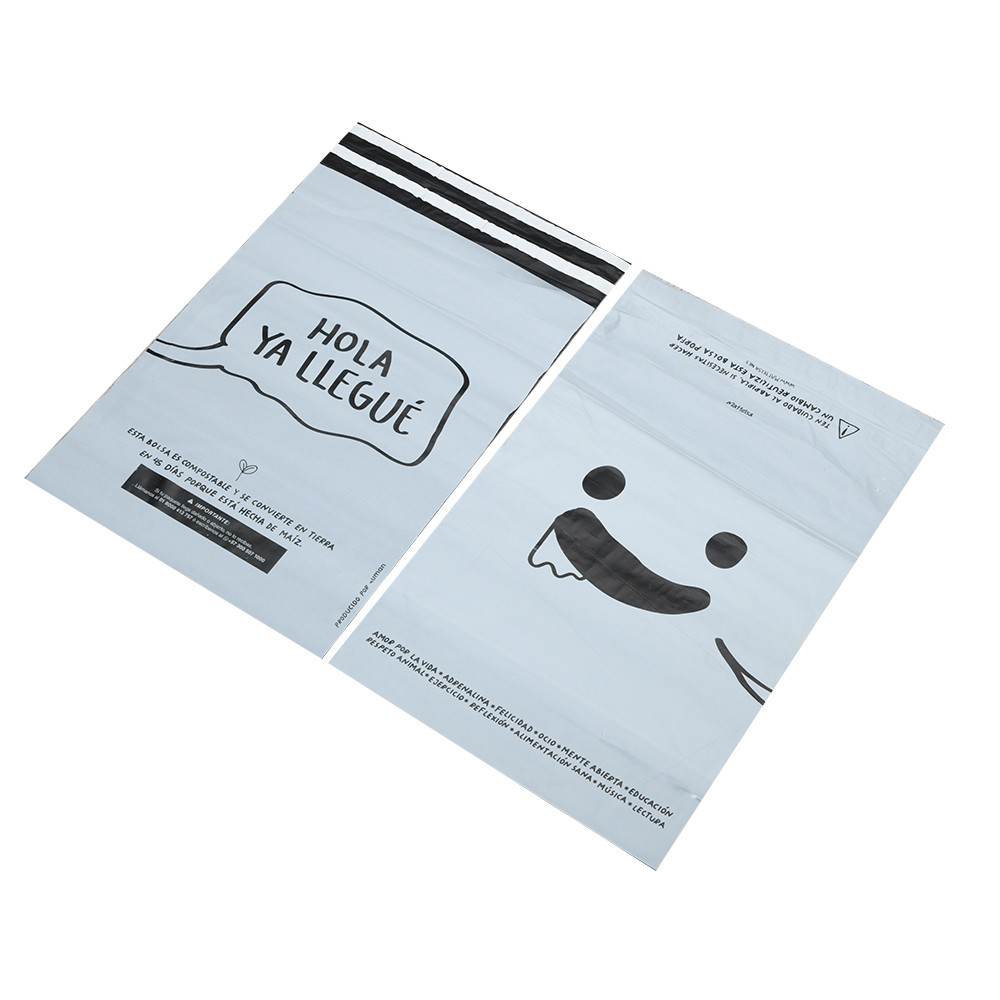

Polylactic acid (PLA), sourced from renewable materials like corn starch, is a leading trend in 2025 for compostable packaging in retail and e-commerce. Its industrial compostability and versatility make it perfect for bags, films, and mailers, addressing the need for durable yet eco-friendly alternatives.

Case Study: Unilever exemplifies this trend, progressing toward its 2025 goal of using 25% recycled plastic in packaging, with 22% achieved in 2024. For flexible packaging, Unilever has incorporated PLA-based films in products like Dove soaps across European markets.

These EN13432-certified films decompose in industrial facilities within 180 days, contributing to a 50% reduction in virgin plastic use by 2025 and diverting significant waste from landfills. This initiative not only meets regulatory demands but also enhances brand loyalty among eco-conscious consumers.

For e-commerce businesses seeking similar benefits, Torise offers Custom Compostable Courier Bags, ideal for shipping with PLA-based durability and full compostability.

Trend 2: Compostable Paper-Based Solutions for Foodservice Packaging

Paper-based compostable packaging, enhanced with plant-derived coatings, is revolutionizing foodservice in 2025 by replacing plastic-lined items like cups and trays. These solutions comply with home and industrial composting standards, supporting stricter regulations like the EU's single-use plastic directives.

Case Study: Starbucks is at the forefront, launching home-compostable paper cups across EMEA in 2025. Featuring a mineral-based coating on paperboard, these EN13432-certified cups break down in backyard compost bins within 90 days and are widely recyclable.

This rollout diverts millions of plastic cups from landfills annually, reducing packaging emissions by up to 15% and aligning with Starbucks' 2030 target of 100% sustainable packaging.

Cafes and restaurants can achieve comparable results with Torise's Custom Compostable Food Accessories, providing leak-resistant, BPI-certified options for efficient waste management.

Trend 3: PBAT and PLA Blends for Flexible Biodegradable Packaging

PBAT and PLA blends are emerging as a 2025 trend for flexible biodegradable packaging, offering strength and compostability for items like grocery bags and produce wraps. These materials meet consumer demands for sustainable alternatives while ensuring regulatory compliance.

Case Study: Tesco, a major UK retailer, is advancing this by aiming for all own-brand packaging to be fully recyclable by December 2025, having already removed over 2.3 billion pieces of plastic from its products.

In its produce sections, Tesco has trialed PBAT-PLA blend bags, certified under OK Compost, which decompose in industrial facilities within six months. This has reduced plastic waste significantly and complied with the UK's Plastic Packaging Tax, with 65% of shoppers preferring the eco-friendly options.

Retailers can implement similar strategies using Torise's Custom Compostable Produce Bags, designed for durability in grocery applications while supporting zero-waste goals.

Why These 2025 Compostable Packaging Trends Matter

The initiatives from Unilever, Starbucks, and Tesco highlight that compostable and biodegradable packaging is both environmentally essential and commercially viable. In 2025, 70% of companies are embedding ESG metrics, with sustainable solutions driving cost efficiencies and consumer trust. Materials like PLA and PBAT, as offered by Torise, enable compliance with certifications while delivering performance.

Join the 2025 Sustainable Packaging Revolution with Torise

With our proven expertise in biodegradable products, Torise Biomaterials supports businesses in adopting these trends. Explore our full range of compostable products to meet global standards and reduce your environmental footprint.